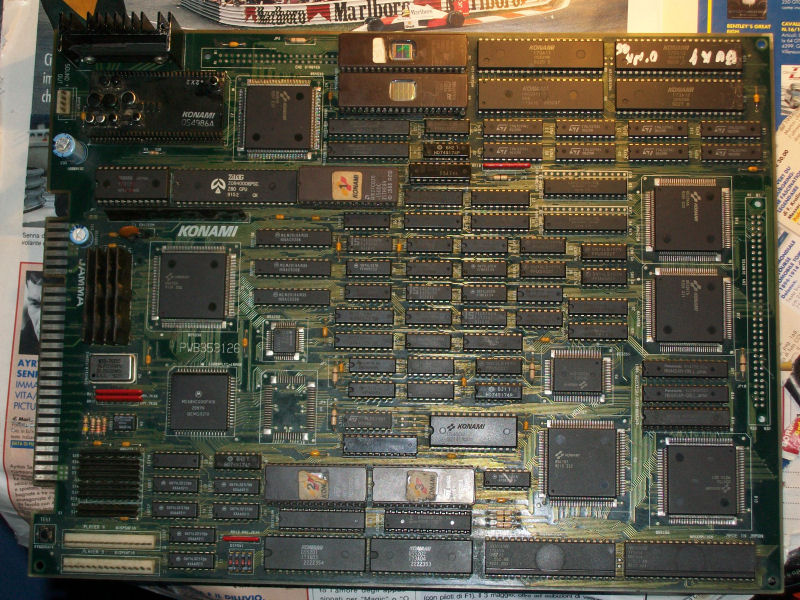

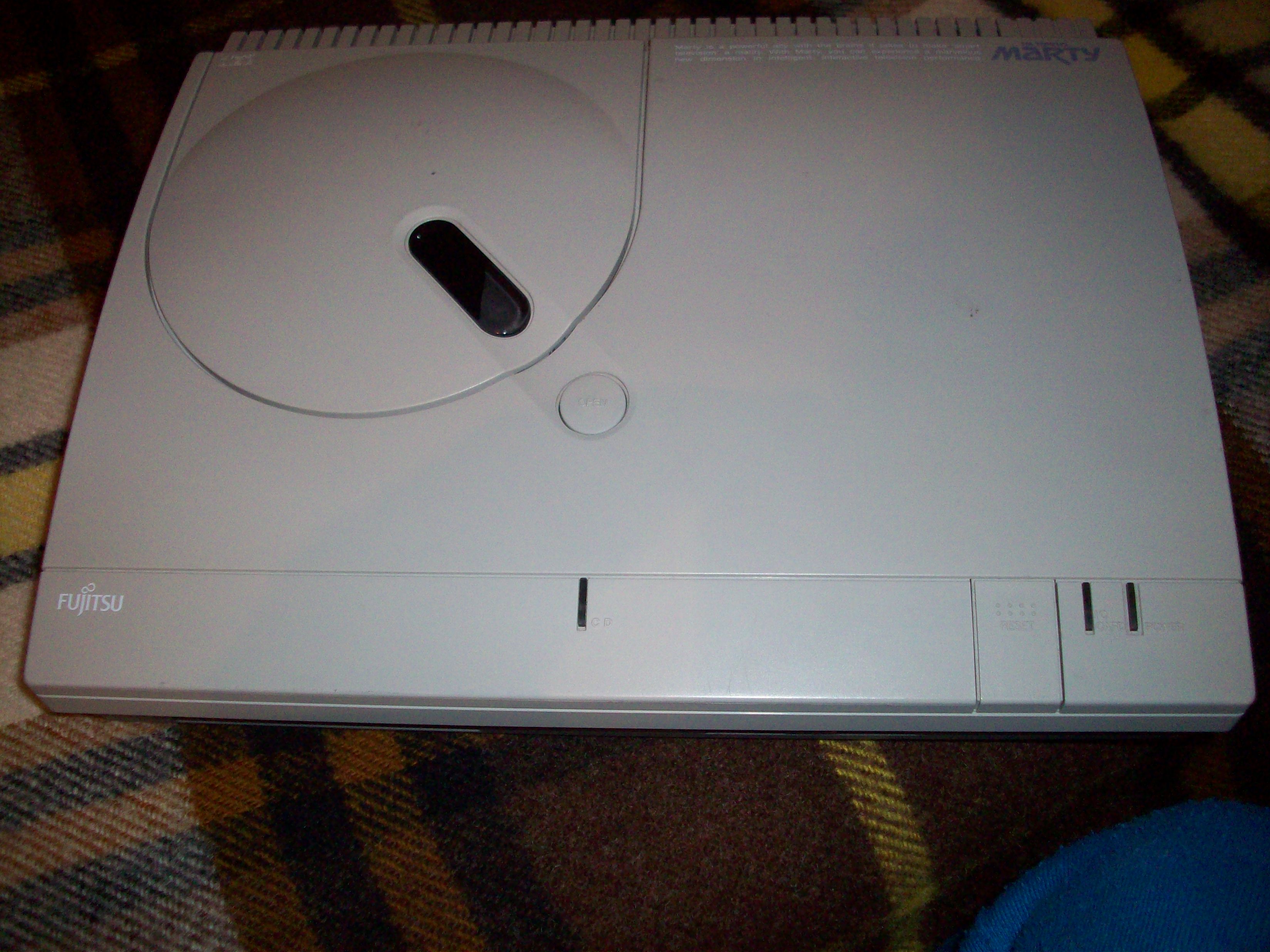

I got from a German customer this nice Fujitsu FM-TOWNS Marty console.

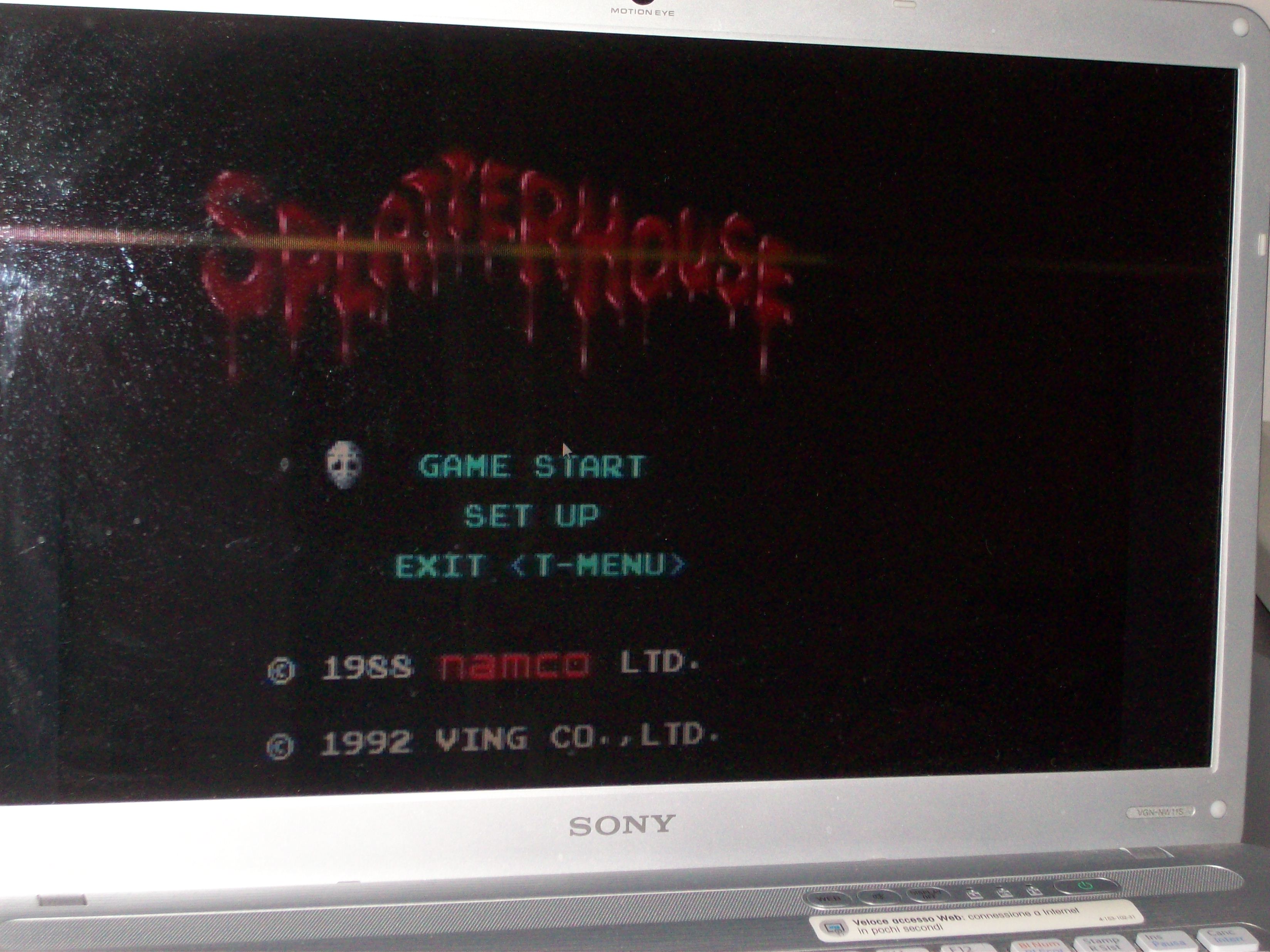

For the uninitiated FM-TOWNS Marty a Japanese console whose hardware is derived from its “big brother” FM-TOWNS computer.It has some of the coolest perfect arcade ports ever published like Splatterhouse, Bubble Bobble, The New Zealand Story, Tatsujin Oh and others.

As every Japanese device it has to be powered by 100V/110V so European people must use a step-down converter capable to reduce our 220V/240V to proper voltage .

This is what the owner of this console forgot to do by mistake..:)

So, after some seconds the “magic smoke” came out from the console.

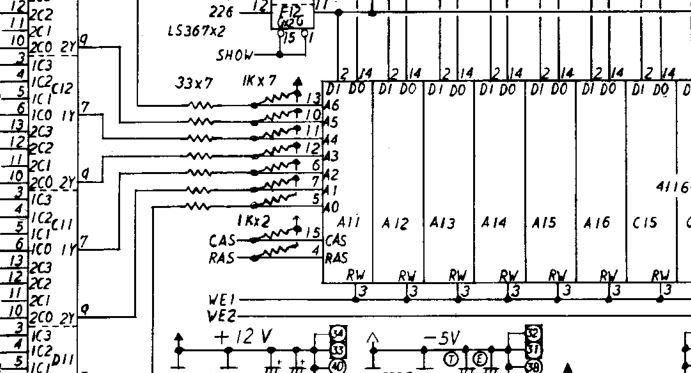

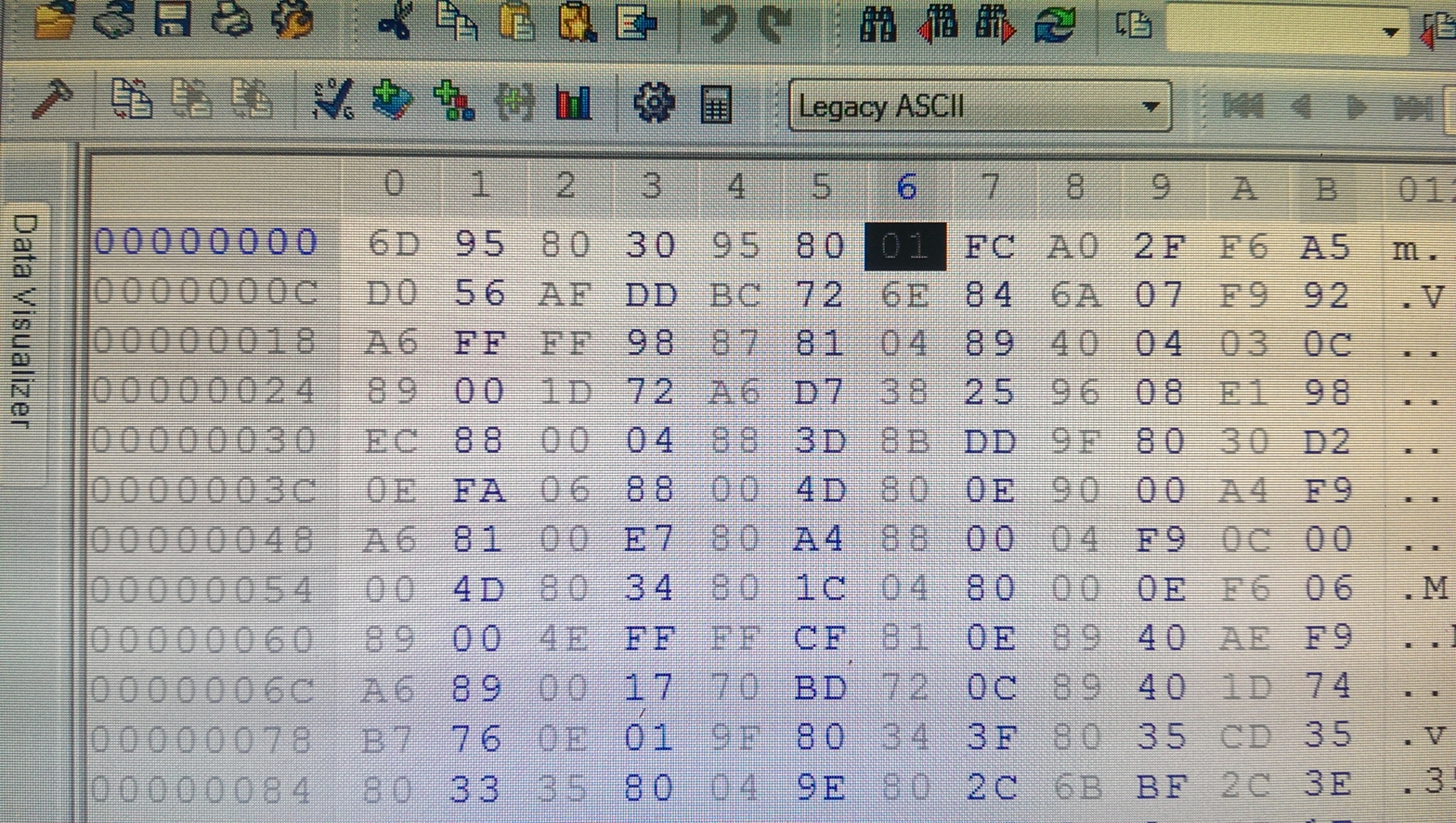

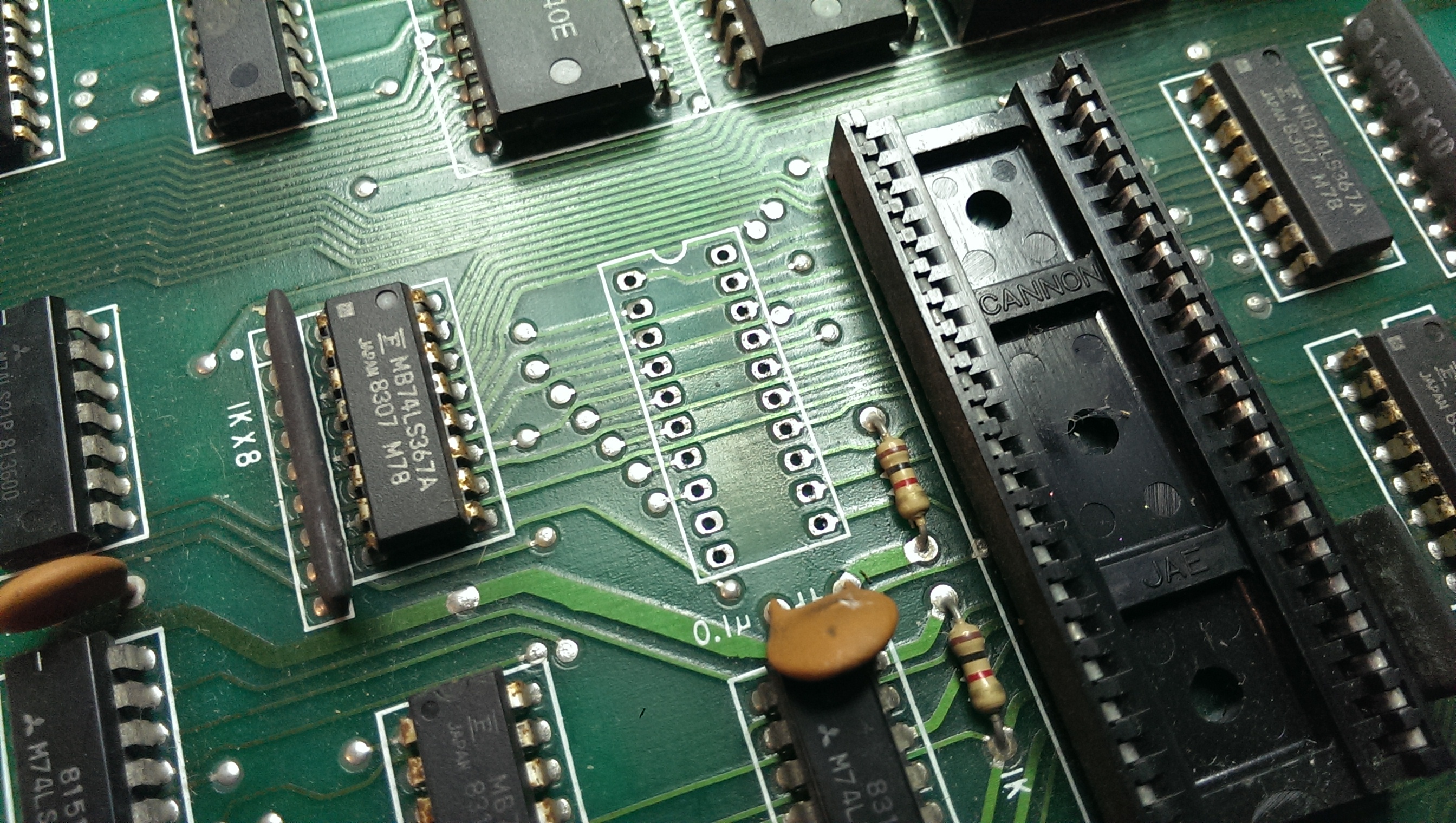

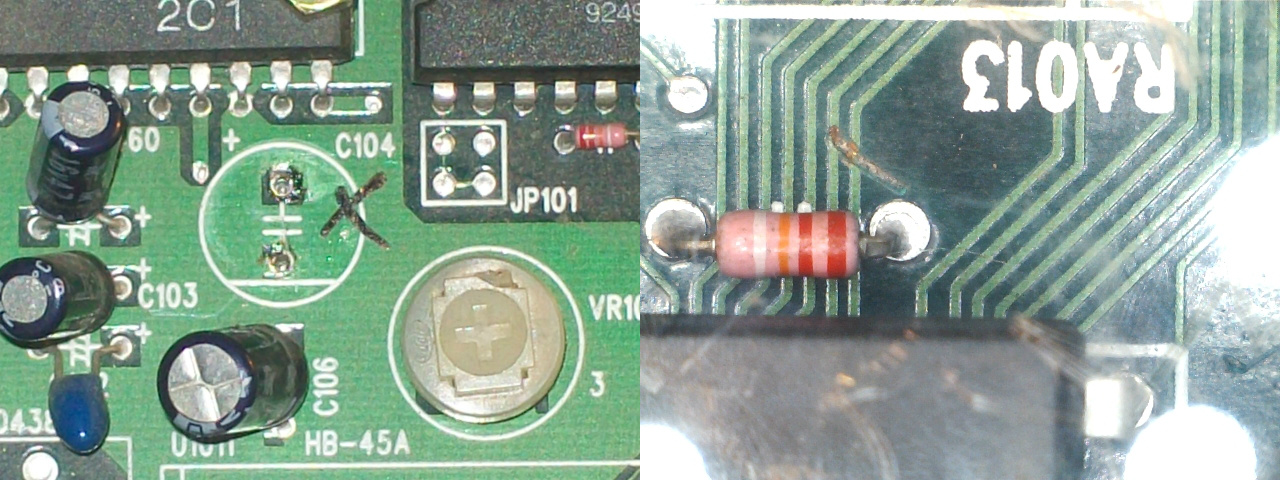

Obviously the console did not power at all so i opened it and I immediately noticed some blown components.In particular the main 2A fuse was blown and a 100uF 200V capacitor was literally exploded on its top.The blown fuse was a good sign since it means he made his duty blocking the excessive current flowing in the circuit but the big 100uf 200V exploded capacitor meant that this overcurrent reached also other components before the main fuse blown up.So, I decided to further investigate.Usually the first component after main fuse and filter capacitor is the bridge rectifier (which, indeed, rectifies the sinusoidal current in continuous one).In my case there was a 600V 1A bridge rectifier marked ‘S1WB S60’, here the datasheet:

Infact, as I suspected, I tested it with a multimeter and it was shorted.

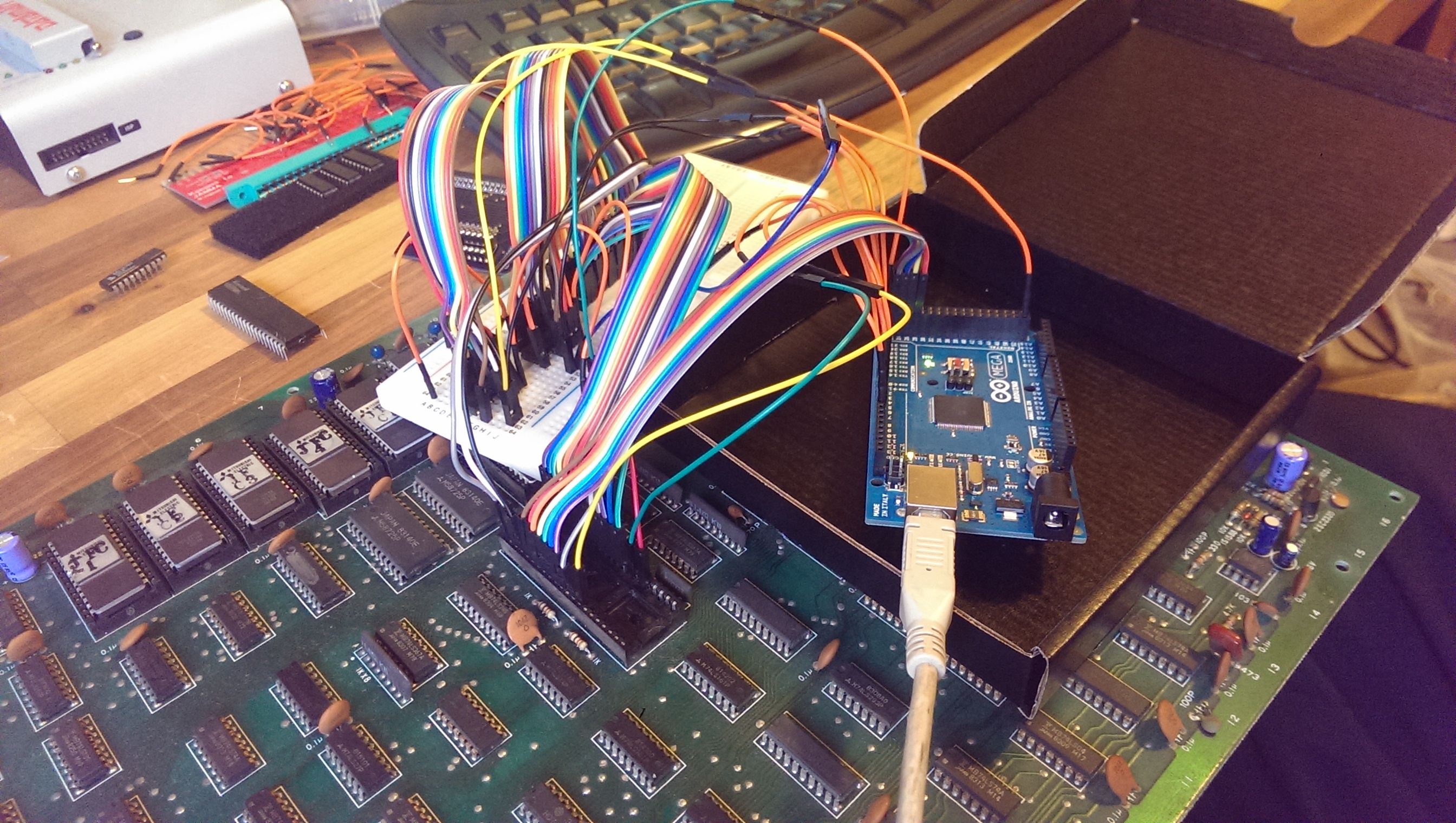

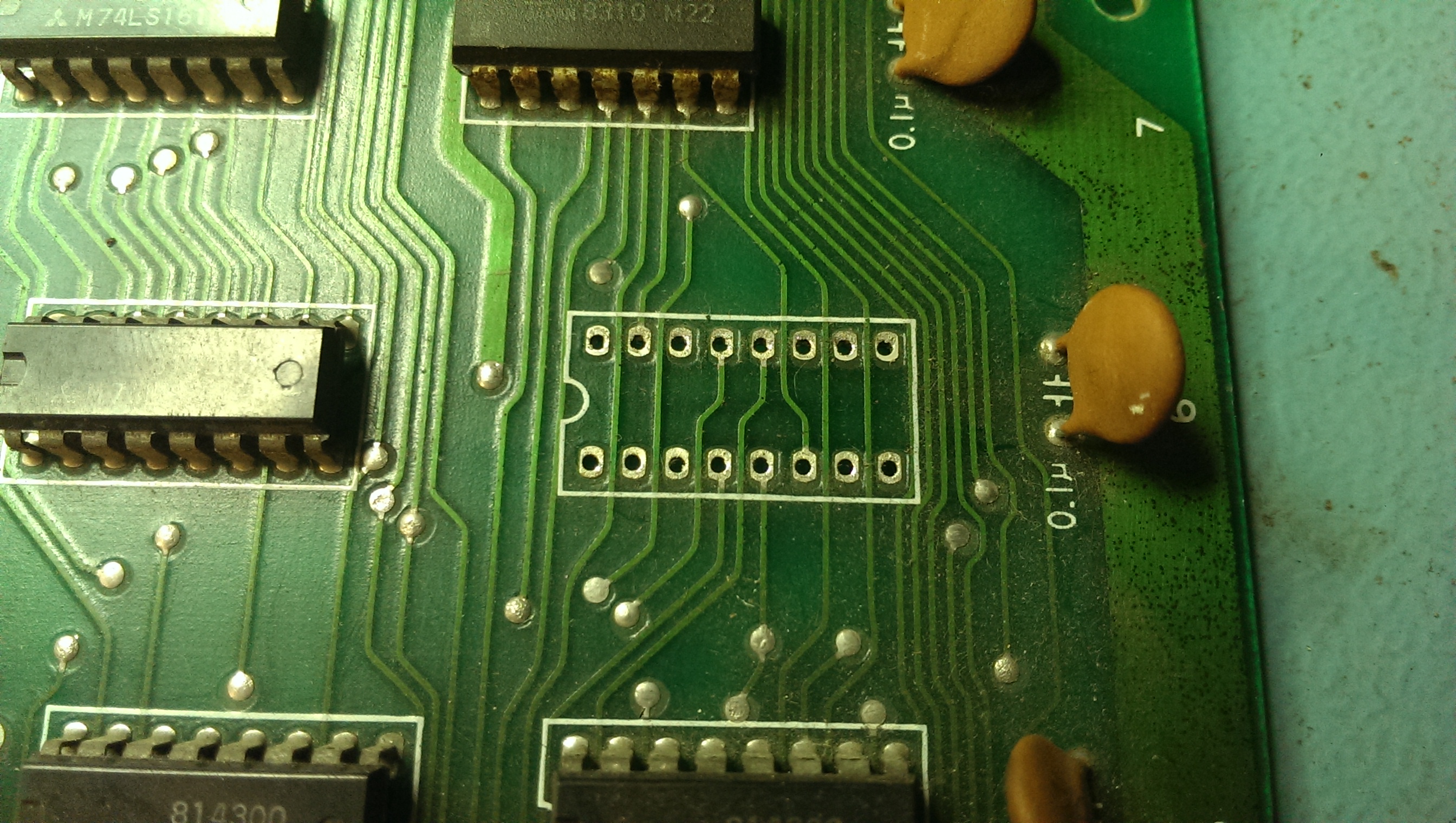

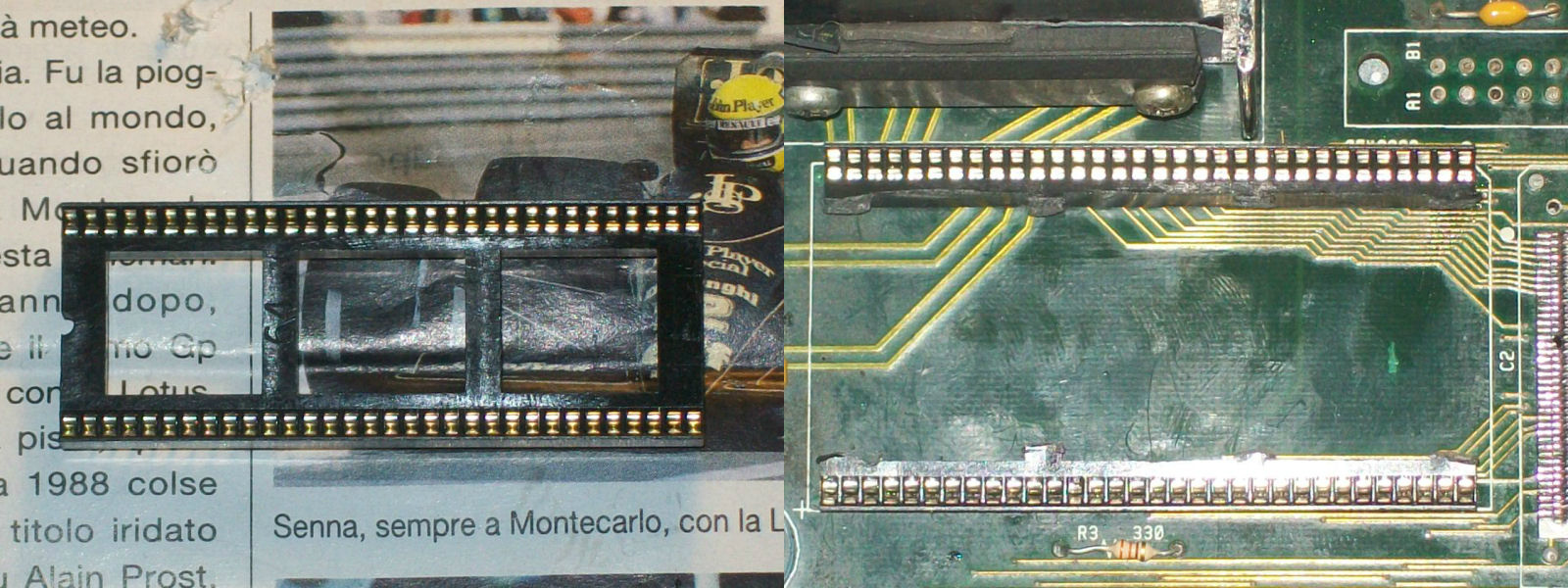

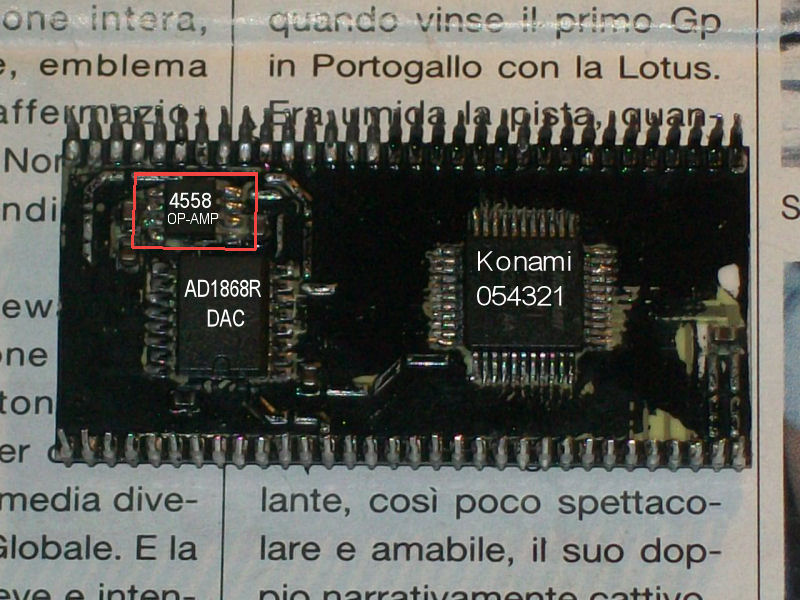

So, I desoldered these three bad components:

and replaced them with equivalent ones:

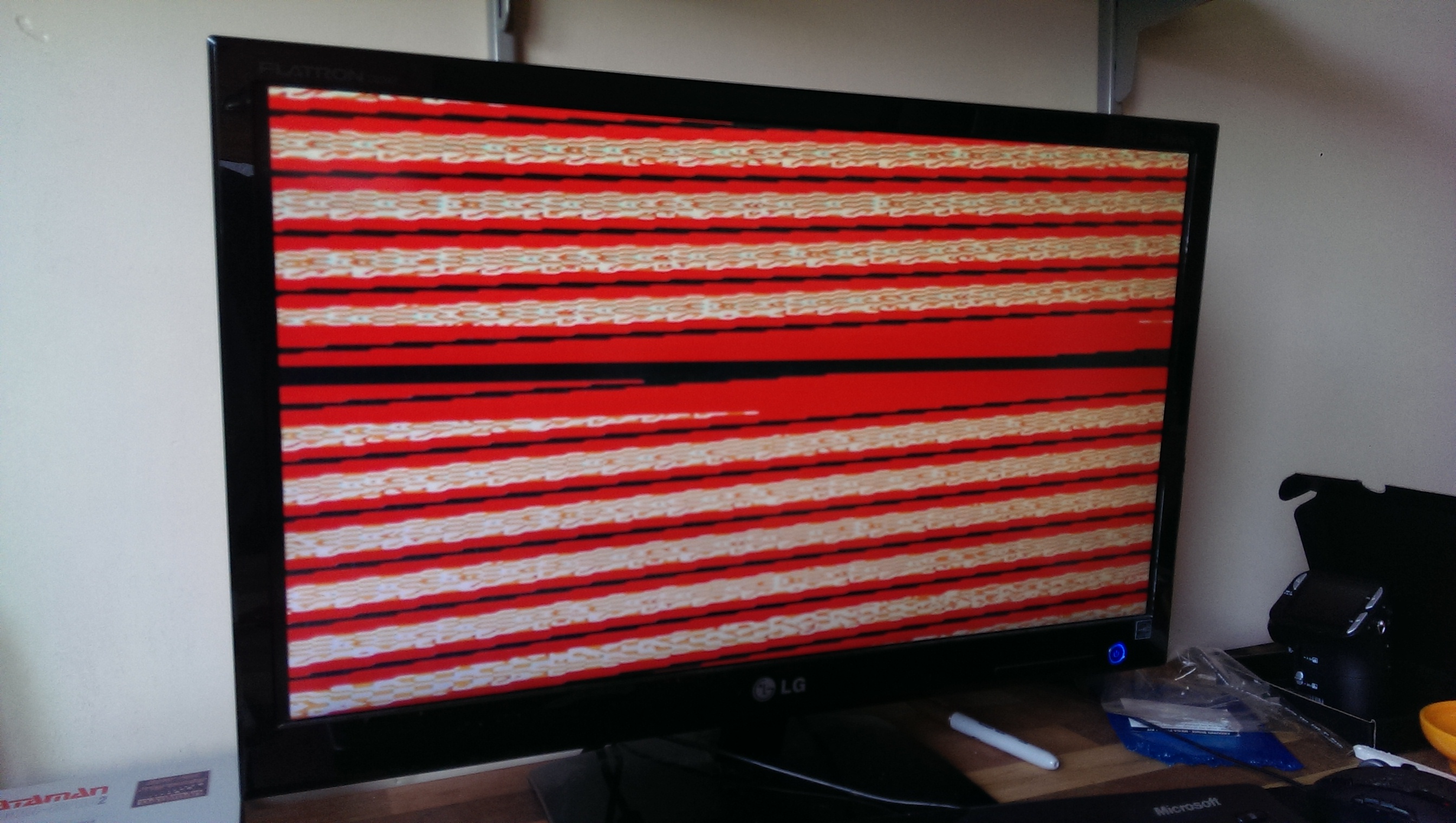

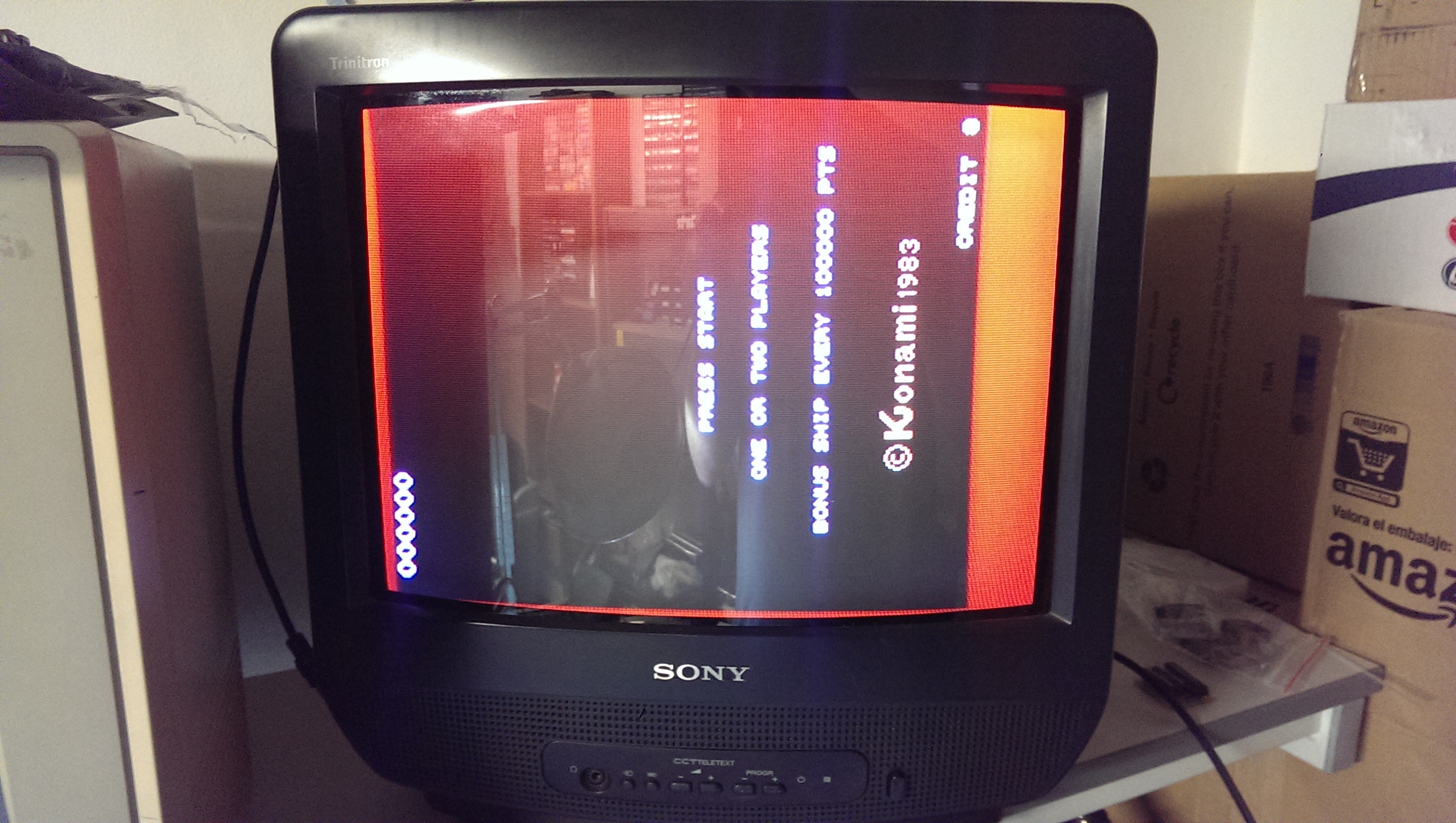

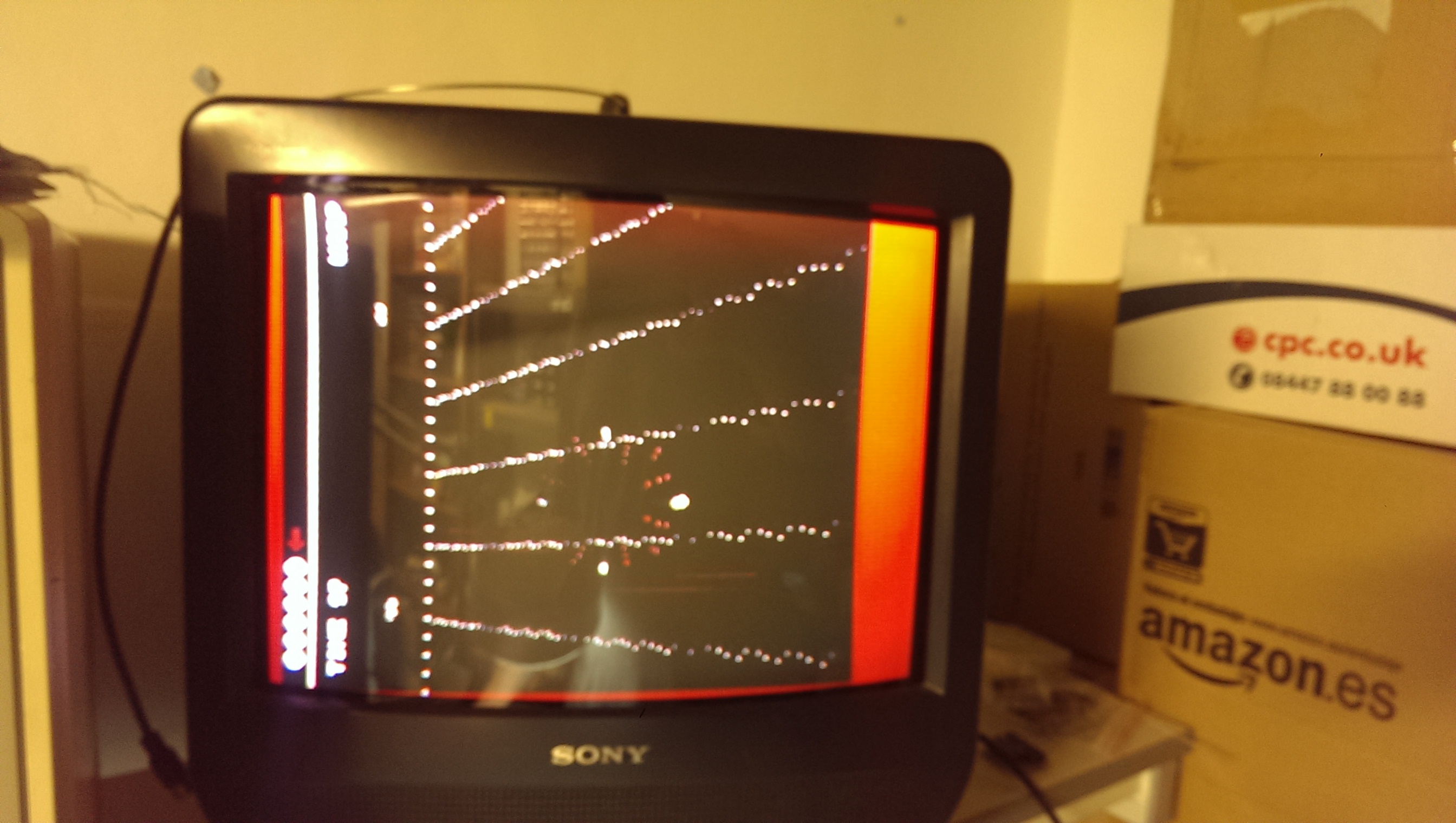

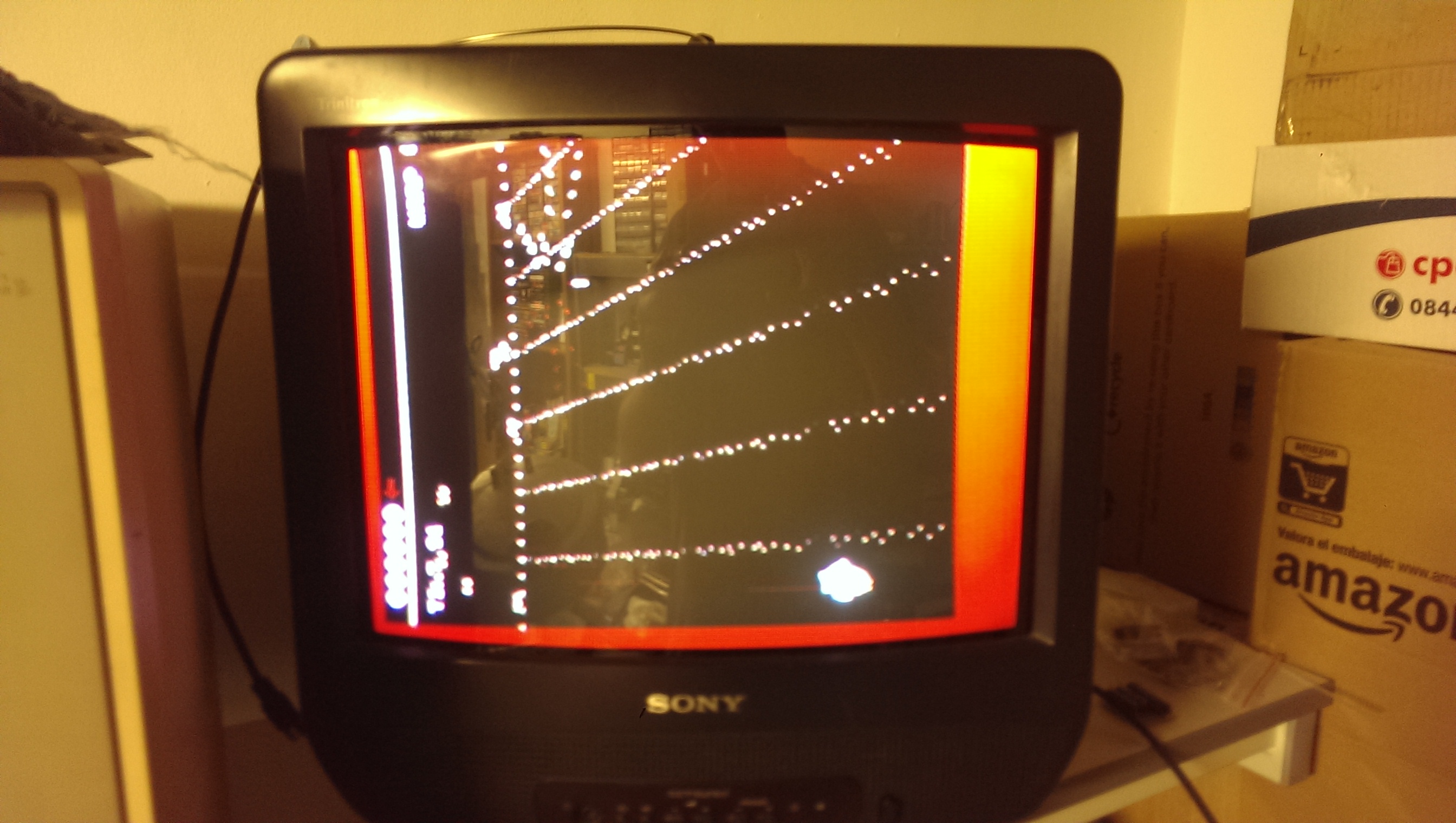

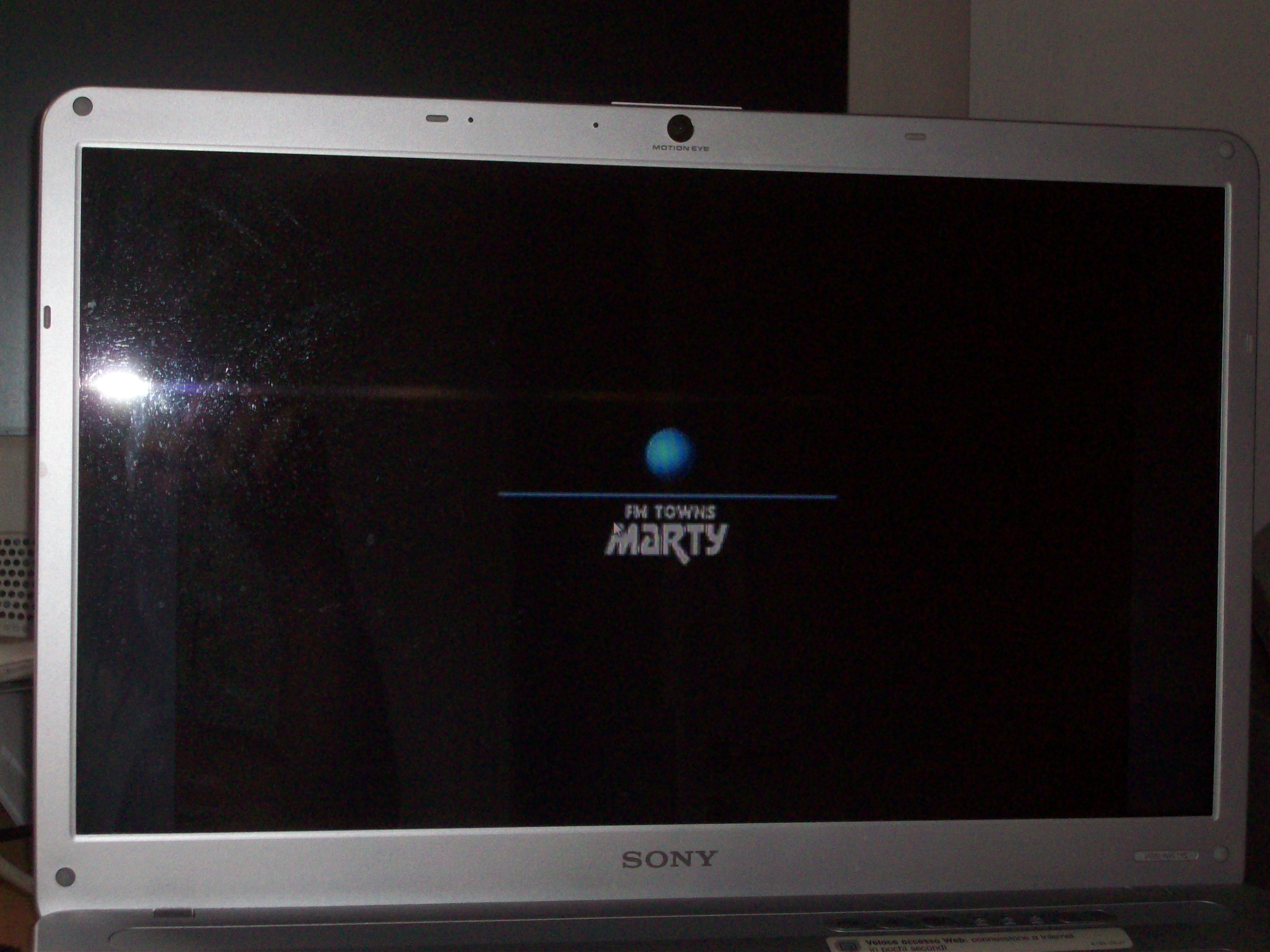

Reassembled the console, powered it and got this:

Mission accomplished.